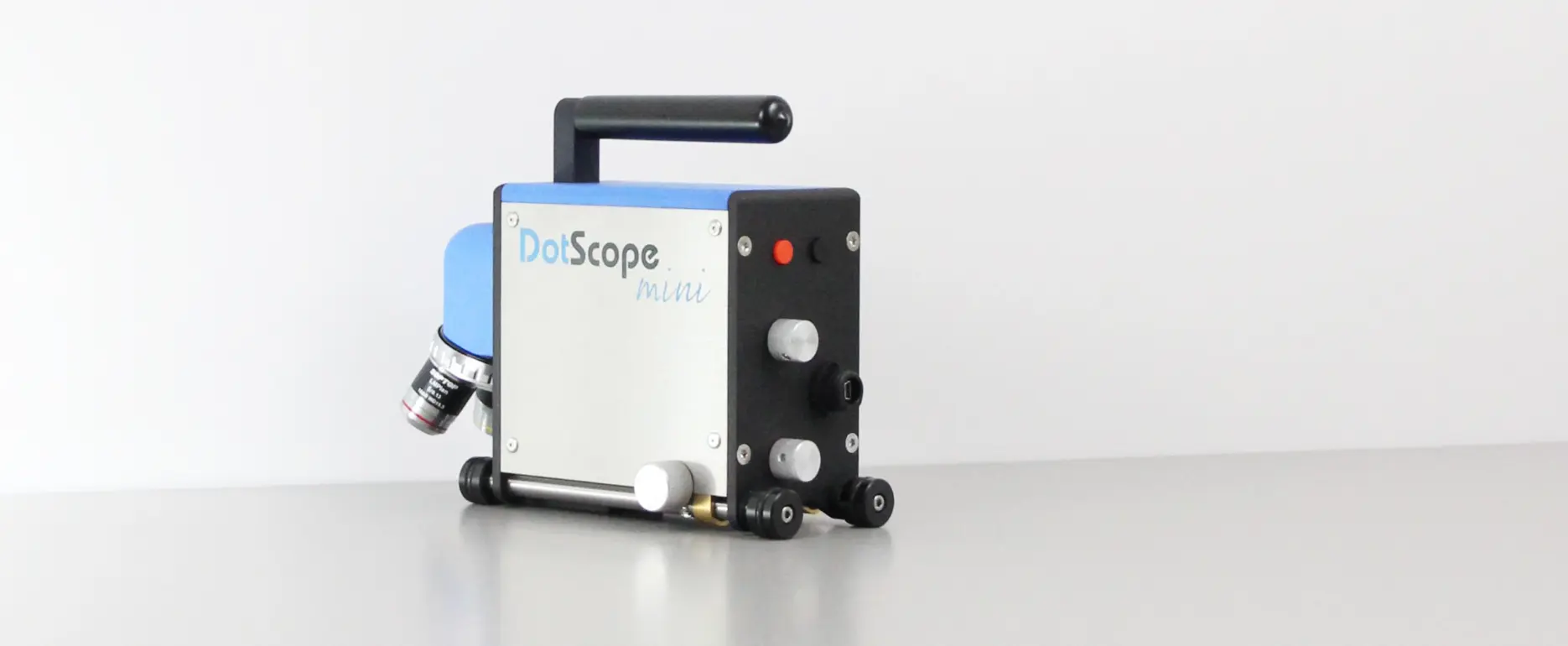

DotScope mini 3D

Leader in the measurement of gravure cylinders

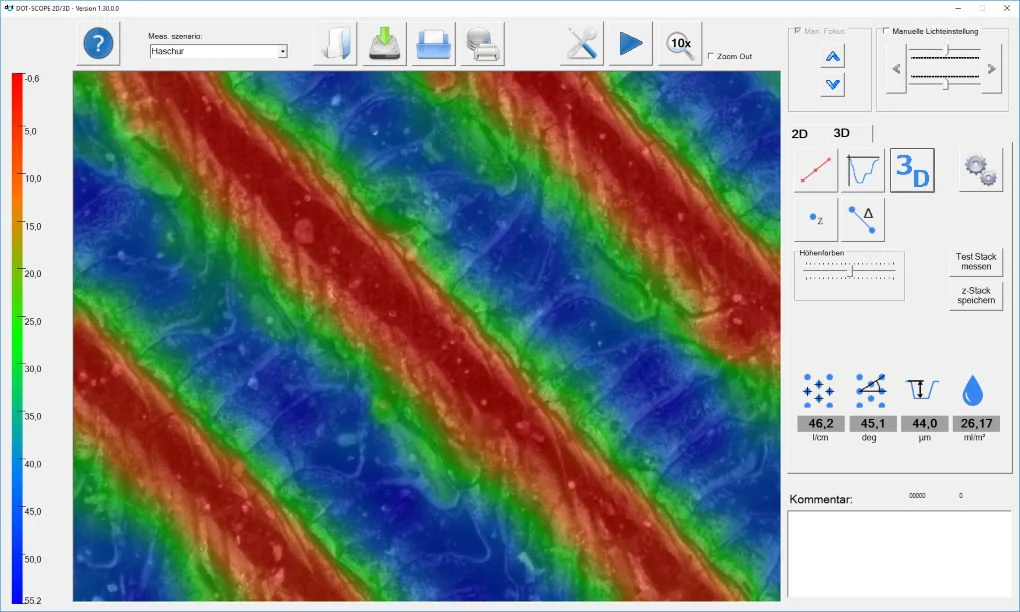

The DotScope mini 3D makes it easy to create 3D views and measurements of microscopically small structures. Operation is extremely simple: position the device in the desired position, move it to the surface or the uppermost position and then click on the measurement button. The microscope adjusts the lighting, takes images of different focal planes and the PC uses these to calculate a 3D model. The surface is automatically recognised and the 3D model is aligned with the surface. The grid is also determined fully automatically. A typical measurement takes only 10…15 seconds in total. The fast image acquisition reduces the influence of external vibrations on the measurement result.

Your benefits

DotScope mini 3d

More than just a promise

Easy handling

Quick lens change

High repetition accuracy

Control buttons on the device

Quick workflow

All-rounder

Maintenance option

Long service life

Control buttons and focussing knob on the DotScope mini

The DotScope mini has control buttons and a knob to focus directly on the device. With the focus knob you can adjust the focus very quickly and precisely. The control buttons are used to control functions, such as starting and saving a measurement, displaying the live image, and resetting the stepper motor position indicator. Advantageous when a large number of measurements have to be carried out or when a depth measurement has to be determined very quickly. This allows the software to be operated remotely, i. you can stay on the device.

Lens turret for quickly changing the magnification

The lens turret with three different lenses allows you to quickly find individual dots in your printing forme. The 5x lens provides an overview, while the other lenses ensure measurement accuracy.

Integrated xy adjustment

The DotScope mini has an xy adjustment, which means that the details of a print form can be approached precisely.

Mobility at the highest level

The DotScope is compact, lightweight and robust and can be transported to the print cylinder with one hand, including the notebook. As the DotScope only requires a USB connection, a high degree of mobility is achieved. The low power consumption in combination with a notebook allows several hours of network-independent use.

Intuitive to use software

The associated software can be operated by anyone in a very short time, even without training, making it ideal for production use. Only one software is required for all applications such as anilox, gravure, flexo and embossing printing. Perfect data preparation includes one-click saving of a measurement, report creation in various languages and layouts as well as database export.

Technical specifications

- Camera sensor resolution: 1280 x 1024 pixels

- Roll diameter: From 60 mm to flat

- Maximum vertical scan range: 2600 μm

- Weight: 2,9 kg

| Lens | Max. measuring field | Min. optical resolution | Screen range l/cm | Screen range lpi |

|---|---|---|---|---|

| 5x | 1400 x 1060 µm² | 1,10 µm/Pixel | 15...60 l/cm | 38...152 lpi |

| 10x | 700 x 530 µm² | 0,55 µm/Pixel | 30...240 l/cm | 76...610 lpi |

| 20x | 350 x 260 µm² | 0,27 µm/Pixel | 60...600 l/cm | 152...1524 lpi |

Your key to maximum Performance

Ready To See What's Next?

Like Nothing You've Seen. Get your quotation for your solution

Let's go!

Your partner for mobile microscopie and quality control in the printing industry.

Address

SOPRIN GmbH

Lise-Meitner-Straße 1-7

24223 Schwentinental, Germany

Contact us

T: +49 4307 2049 570

E: info[@]soprin-gmbh.de