DotScope mini 2D

The most efficient way

to measure gravure cylinders

All components of the DotScope mini 2D are designed to maximise productivity. Measurements can be carried out and saved using buttons without having to remove the measuring device from your hand. Measurements are taken automatically and refocussing is often unnecessary.

Your benefits

DotScope mini 2d

For gravure power users

Easy handling

Quick lens change

High repetition accuracy

Control buttons on the device

Quick workflow

Power users in gravure printing

Maintenance option

Long service life

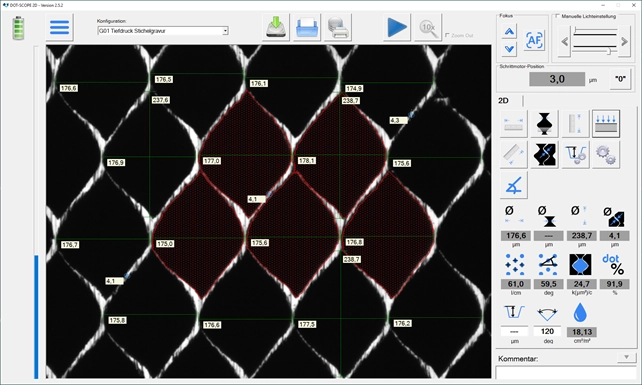

Gravure engraving application

- Transverse diagonal

- Longitudinal diagonal

- Cut-through (channel)

- Wall width

- Screen width

- Screen angle

- Cell area

- Cell area percentage (dot%)

- If the stylus angle is specifi ed, calculation of the theoretical dip volume in cm³/m², BCM or µm³/cell

- Reliable measurement even with very narrow walls

- Transverse diagonal

- Longitudinal diagonal

- Cut-through (channel)

- Wall width

- Diagonal

- Angle

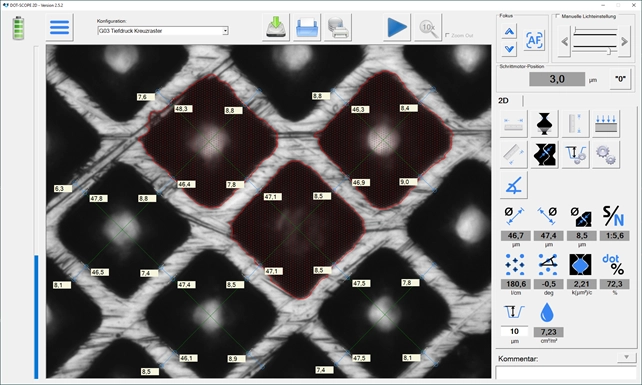

Rotogravure cross screen application

- Diagonal A

- Diagonal B

- Wall width

- Wall cell ratio (S/N)

- Screen width

- Screen angle

- Cell area

- Cell area percentage (dot%)

- If the stylus angle is specifi ed, calculation of the

theoretical dip volume in cm³/m², BCM or µm³/cell

- Transverse diagonal

- Longitudinal diagonal

- Cut-through (channel)

- Wall width

- Diagonal

- Angle

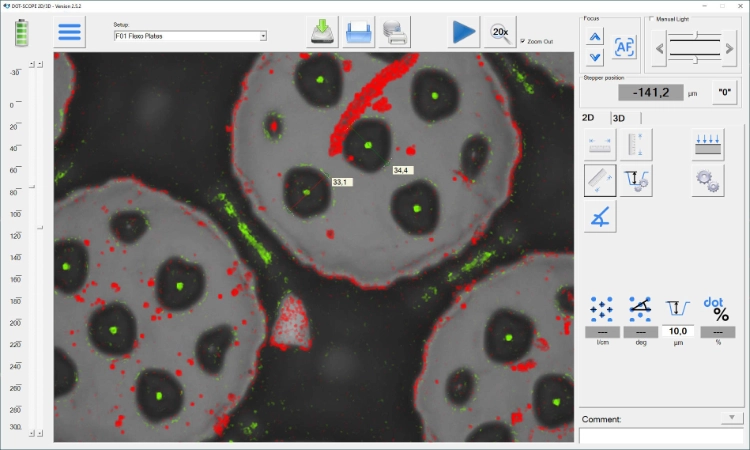

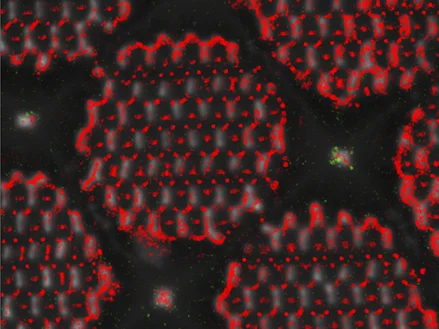

MicroCell analysis

- Diagonal of the MicroCell

- Depth measurement

Depth measurement with z-Scan

With the depth scan, the depth of structures can be measured with software support.

- Documentability of the depth measurement

- More accurate and reproducible determination of the measured depth value

- In general, an object with a lower magnifi cation level can be selected than with purely manual measurement. This increases the lateral fi eld of view accordingly.

Versatile functions for documentation and archiving

- Save and load measurement

- Print measurement report

- Database connection

- Create JPG image

Technical specifications

- Camera sensor resolution: 1280 x 1024 pixels

- Roll diameter: From 60 mm to flat

- Weight: 2,9 kg

| Lens | Max. measuring field | Min. optical resolution | Screen range l/cm | Screen range lpi |

|---|---|---|---|---|

| 5x | 1400 x 1060 µm² | 1,10 µm/Pixel | 15...60 l/cm | 38...152 lpi |

| 10x | 700 x 530 µm² | 0,55 µm/Pixel | 30...240 l/cm | 76...610 lpi |

| 20x | 350 x 260 µm² | 0,27 µm/Pixel | 60...600 l/cm | 152...1524 lpi |

Your key to maximum Performance

Ready To See What's Next?

Like Nothing You've Seen. Get your quotation for your solution

Let's go!

Your partner for mobile microscopie and quality control in the printing industry.

Address

SOPRIN GmbH

Lise-Meitner-Straße 1-7

24223 Schwentinental, Germany

Contact us

T: +49 4307 2049 570

E: info[@]soprin-gmbh.de